As of March 2014 there were approximately 1.1 million oil and gas wells in the United States, a direct consequence of technological advances that have increased domestic energy production to levels unseen since the 1970s. Much of the growth has been in natural gas obtained through hydraulic fracturing, or “fracking,” which involves injecting immense quantities of water and chemicals into the ground to fracture the rock and release deposits that would otherwise be inaccessible.

The growth in the number of wells is in part a function of how fracked wells behave over time, in particular “tight oil” deposits, generally shale or sandstone: Well production starts high, but can fall anywhere from 40% to 70% a year thereafter. To maintain the same overall level of production, more and more wells must be drilled, often in lower-grade formations — the “sweet spots” are drilled first, after all. A 2013 study by the University of Texas of more than 16,000 wells in the state’s Barnett Shale region found that its production will peak around 2015, and decline slowly thereafter, and this despite 15,000 more wells being drilled by 2030. This has been called the “Red Queen” syndrome, named after the Alice in Wonderland character who must run faster and faster just to stay in the same place.

A 2013 Wall Street Journal investigation found that since 2000, more than 15 million U.S. residents live within a mile of a well that has been fracked. In Johnson County, Texas, alone, nearly 4,000 wells have been drilled since 2000. For every well across the United States, a seemingly endless flow of trucks must haul in gravel, pipes, water and chemicals, then haul out liquid fuels and waste — anywhere from 600 to 1,000 one-way trips for the fracking phase alone. In addition to the potential environmental and health risks of fracking itself for nearby residents, all of this heavy-truck traffic imposes substantial external costs, including noise and pollution.

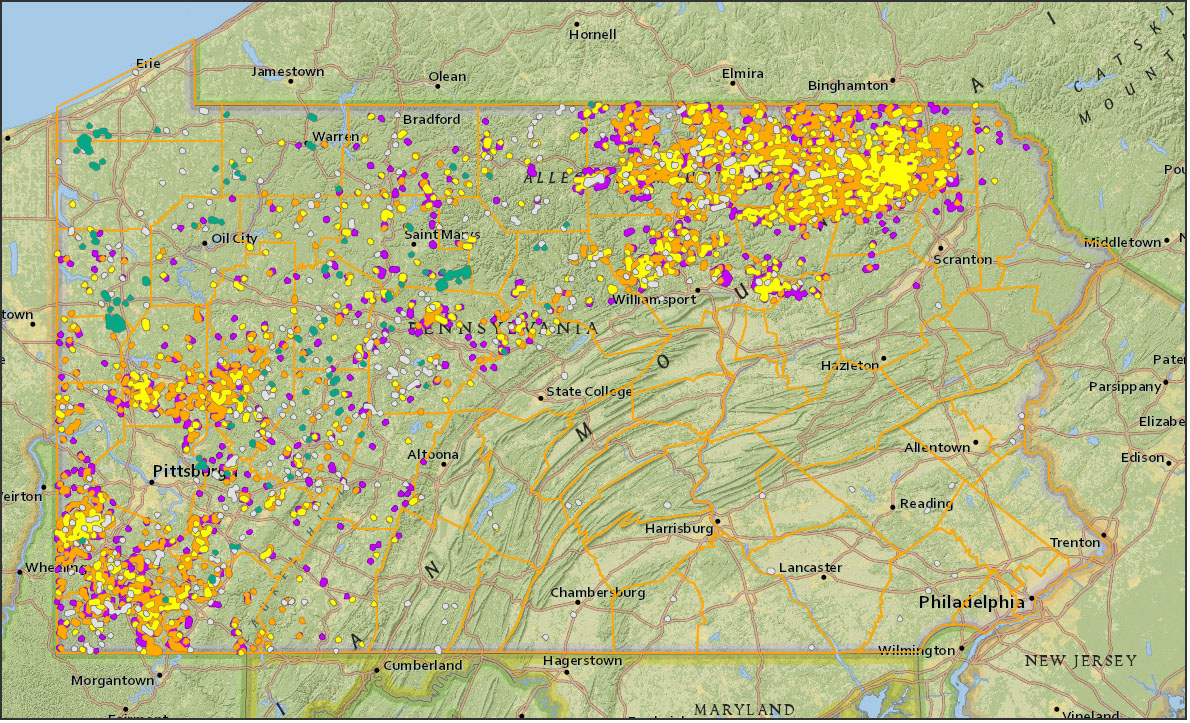

A 2014 study published in Journal of Infrastructure Systems, “Estimating the Consumptive Use Costs of Shale Natural Gas Extraction on Pennsylvania Roadways,” analyzes a less-studied impact of fracking, the damage it imposes on local transportation infrastructure. The researchers, based at the RAND Corporation and Carnegie Mellon University, looked at the design life and reconstruction cost of roadways in the Marcellus Shale formation in Pennsylvania. They note that local roads are generally designed to support passenger vehicles, not heavy trucks, and that “the useful life of a roadway is directly related to the frequency and weight of truck traffic using the roadway.”

The study’s findings include:

- Heavier vehicles cause exponentially greater roadway damage: A single axle with a 3,000-pounds load has a load equivalency factor (LEF) of 0.0011; for an 18,000-pound load, the LEF is 1.0; and for 30,000 pounds, it’s 8.28. “This means that 18,000-pound and 30,000-pound single-axle … do about 900 times and 7,500 times more damage than a 3,000-pound single axle pass, respectively.”

- The estimated road-reconstruction costs associated with a single horizontal well range from $13,000 to $23,000. However, Pennsylvania often negotiates with drilling companies to rebuild smaller roads that are visibly damaged, so the researchers’ conservative estimate of uncompensated roadway damage is $5,000 and $10,000 per well.

- While the per-well figure of $5,000-$10,000 appears small, the increasingly large number of wells being drilled means that substantial costs fall on the state: “Because there were more than 1,700 horizontal wells drilled [in Pennsylvania] in 2011, the statewide range of consumptive road costs for that year was between $8.5 and $39 million,” costs paid by state transportation authorities, and thus taxpayers.

“Some external costs, such as air-quality related health problems, are borne by society at large,” the scholars conclude, “but roadway consumption costs accrue directly to the state and local departments of transportation (e.g., PennDOT).” They suggest several potential approaches that the Commonwealth of Pennsylvania could take to reduce these costs, including an additional fee or tax on top of current per-well impact fees, limiting truck size and weight, or encouraging the use of pipelines rather than trucks. “A comprehensive policy design would combine elements of these three approaches, and work in conjunction with other policies to reduce the broader set of external costs from shale gas operations.”

Related research: A 2013 study published in the Proceedings of the National Academy of Sciences (PNAS), “Anthropogenic Emissions of Methane in the United States,” seeks to better quantify the current levels, regions and sectors that are the key sources of the potent greenhouse gas. The study found that current U.S. methane emissions appear to be significantly higher than previous estimates — 1.5 times greater than those by the U.S. Environmental Protection Agency and 1.7 times greater than data from the European Environmental Agency’s Emission Database for Global Atmospheric Research.

Also of interest is “Fracking, Shale Gas and Health Effects,” a roundup of recent research on the potential health impacts of shale gas extraction and fracking. One of the studies examined is “Methane Contamination of Drinking Water Accompanying Gas-Well Drilling and Hydraulic Fracturing.” It finds that “in active gas-extraction areas (one or more gas wells within 1 km), average and maximum methane concentrations in drinking-water wells increased with proximity to the nearest gas well and were 19.2 and 64 mg CH4 L-1 (n = 26), a potential explosion hazard.”

Keywords: fossil fuels, global warming, climate change, massive hydraulic fracturing, fracking, infrastructure, Barnet Shale, Marcellus Shale, greenhouse gases, @leightonwalter, @journoresource

Expert Commentary